All Categories

all-categories

As a steel service center, we always have a deep and diverse inventory of material in stock and ready to form. Along with stainless steel, hot rolled steel, and cold rolled steel, we process heat-treated grades, galvanized steel, mild steel, and HSLA steel. We create channels, structural channels, structural tees, and many other profiles and configurations. Our highly efficient and precise press brakes feature CNC controls to provide a high degree of repeatable accuracy.

Several different finishing options and secondary services are available. We can create custom tooling, clean and shot blast, tap holes, and deburr. Finishing options include plating, anodizing, and painting. We also offer various heat treatments. Press brake forming can also be combined with other services, such as plasma cutting, punching, shearing, plate rolling, etc.

Along with monopoles and transmission poles, we provide press brake formed parts for use as frame rails, bridge and crane girders, channels, and more. We operate with lean efficiency and turn jobs around quickly. For more information about our press brake forming services or any other pre-production processing capabilities, contact us directly. /Asset/ST4C0988.jpg

We operate a range of large capacity processing equipment capable of upholding a high standard of quality and precision. Along with plasma and oxy-fuel cutting machines, press brakes, saws, and shears, our equipment lineup includes large bed CNC drills, a punch press, and beam cambering equipment. We cut to length, drill and tap holes, create countersinks and counterbores, mill features, etc.

We operate out of multiple locations and serve diverse industries such as industrial and commercial construction, industrial transmission and telecommunication, OEM, marine, and shipbuilding. Strong vendor relationships with steel mills and our purchasing power allow us to offer an extensive product mix and competitive pricing. Our steel center services are backed up by a team of approximately 400 men and women with phenomenal skills and a passion for providing the highest level of service to each and every customer. For more information about our steel center services and our pre-production processing capabilities, contact us directly. /Asset/FR5A9665.jpg

Wide Flange Beam

(279) Delta Steel stocks WF Beams from W4 x 13 to W44 x 335 in. in various lengths up to 70 ft to help our customers minimize scrap. /Asset/w1.JPGSquare and Rectangle Tube

(448) Delta Steel stocks tubing from 1/2 x 1/2 in square to 34 x 10 in rectangle in various lengths up to 60 ft to help our customers minimize scrap. Select sizes available galvanized. /Asset/w2.JPGPipe and Round Tube

(286) Delta Steel stocks pipe from 1/2 in Schedule 40 to 20 in XH, and round tube from 1 1/2 in to 10 in OD from 21 ft to 60 ft in various lengths to help our customers minimize scrap. Select sizes available galvanized. /Asset/w3.JPGAngle

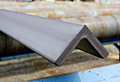

(142) Delta Steel stocks angles from L1/2 in x 1/2 in x 1/8 in up to L10 in x 10 in x 3/4 in. in 20 ft and 40 ft lengths. 8 in Angles are stocked up to 60 ft lengths in 10 ft increments. /Asset/w21.JPGFlat Bar

(321) Delta Steel stocks Flats from FL 1/8 in x 1/2 in up to FL 2 in x 8 in. in 20 ft lengths. Many sizes also available in 40 ft lengths. Select sizes available galvanized. /Asset/w4.JPG

Round Bar and Rebar

(87) Delta Steel stocks rounds from 1/4 in to 2 1/2 in and rebar from #3 to #8 in 20 ft lengths. Many rounds also available in 40 ft lengths. /Asset/bar-gratings.jpgSquare

(15) Delta Steel stocks squares from 3/8 to 2 1/2 in and bar channels from BC 1 x 1/2 x 1/8 in to BC2 x 1 x 3/16 in. /Asset/w7.JPG

Bar Grating and Expanded Metal

(18) Delta Steel stocks bar grating in 1 in x 3/16 in to 2 1/2 in x 3/16 in. in pattern sizes in both unpainted and galvanized finishes. Delta stocks expanded metal in 3/4 in x 9 to 1 1/2 in x 9 in flat, grating, and raised profiles. /Asset/Grating.jpgSheet and Floor Plate

(33) Delta Steel stocks plate in 3/16 in to 8 in thick in several pattern sizes up to 120 in x 480 in. Delta stocks sheet from 16 to 10 ga. in several pattern sizes and floor plate from 14 ga to 1 in thick in several pattern sizes. /Asset/w9.JPGChannel

(31) Delta Steel stocks channels from a C3 x 4.1 to C15 x 50 in various lengths up to 60 ft to help our customers minimize scrap. Select sizes available galvanized. /Asset/w10.JPGMiscellaneous Channel

(57) Delta Steel stocks MC channels from a MC3 x 7.1 to MC18 x 58 in various lengths up to 60 ft to help our customers minimize scrap. /Asset/w11.JPGI-Beam

(31) Delta Steel stocks I-Beams from a S3 x 5.7 to S24 x 121 in various lengths up to 60 ft to help our customers minimize scrap. /Asset/w12.JPG

Press Brake Forming Services

As part of our pre-production processing capabilities, at Delta Steel, we offer press brake forming services. We have an extensive selection of tooling and die sets and press brakes rated in the 2,200-ton to 3,000-ton range. Our press brake forming services are adaptable to a wide variety of sheet metal fabrications, and we can process sheets measuring up to 60' in length.As a steel service center, we always have a deep and diverse inventory of material in stock and ready to form. Along with stainless steel, hot rolled steel, and cold rolled steel, we process heat-treated grades, galvanized steel, mild steel, and HSLA steel. We create channels, structural channels, structural tees, and many other profiles and configurations. Our highly efficient and precise press brakes feature CNC controls to provide a high degree of repeatable accuracy.

Several different finishing options and secondary services are available. We can create custom tooling, clean and shot blast, tap holes, and deburr. Finishing options include plating, anodizing, and painting. We also offer various heat treatments. Press brake forming can also be combined with other services, such as plasma cutting, punching, shearing, plate rolling, etc.

Along with monopoles and transmission poles, we provide press brake formed parts for use as frame rails, bridge and crane girders, channels, and more. We operate with lean efficiency and turn jobs around quickly. For more information about our press brake forming services or any other pre-production processing capabilities, contact us directly. /Asset/ST4C0988.jpg

Steel Service Centers

At Delta Steel, we have been in business for more than 50 years as a steel service center and are one of the largest service centers in the Southwestern United States. We carry a deep and diverse inventory and offer an extensive range of pre-production processing capabilities. Along with hot rolled, cold rolled, and hot-rolled pickled and oiled steel, we inventory structural steel and stainless steel grades. We offer coil, sheet, plate, square and rectangular tubes, flat and round bar, rebar, and a wide range of beam, channel, and angle configurations.We operate a range of large capacity processing equipment capable of upholding a high standard of quality and precision. Along with plasma and oxy-fuel cutting machines, press brakes, saws, and shears, our equipment lineup includes large bed CNC drills, a punch press, and beam cambering equipment. We cut to length, drill and tap holes, create countersinks and counterbores, mill features, etc.

We operate out of multiple locations and serve diverse industries such as industrial and commercial construction, industrial transmission and telecommunication, OEM, marine, and shipbuilding. Strong vendor relationships with steel mills and our purchasing power allow us to offer an extensive product mix and competitive pricing. Our steel center services are backed up by a team of approximately 400 men and women with phenomenal skills and a passion for providing the highest level of service to each and every customer. For more information about our steel center services and our pre-production processing capabilities, contact us directly. /Asset/FR5A9665.jpg